Agility and efficiency are paramount in today’s VUCA world, in such a scenario, supply chain visibility has emerged as a pivotal driver of success. The ability to track, analyze, and optimize every aspect of the supply chain has become a competitive advantage that no forward-thinking company can afford to overlook.

A good example of supply chain ambiguity is the global chip shortage, which has been causing disruptions to a wide range of industries since 2020. The shortage is due to a number of factors, including increased demand for chips during the pandemic, supply chain disruptions caused by COVID-19, and natural disasters such as the Texas winter storm in 2021.

One of the main challenges caused by the chip shortage is that it has been difficult for companies to track and manage their chip inventory. This is because many companies do not have full visibility into their supply chains, and they rely on their suppliers to provide them with accurate information about chip availability and delivery times.

Tesla is one of the companies that has been hardest hit by the chip shortage. In January 2022, Tesla CEO Elon Musk said that the chip shortage was the company’s “biggest challenge”. Musk also said that Tesla was having to “make a lot of changes” to its production lines in order to deal with the shortage.

One of the major problems that Tesla has faced is that it does not have full visibility into its supply chain. This is because Tesla relies on a number of different suppliers for its chips. As a result, Tesla has found it difficult to track down alternative suppliers or to get accurate information about chip availability and delivery times.

This lack of visibility has led to delays in the production of Tesla vehicles. For example, in January 2022, Tesla had to delay the start of production of its new Cybertruck model due to a lack of chips.

As a result of this lack of visibility, many companies have been caught off guard by the chip shortage and have had to scramble to find alternative suppliers or reduce production. This has led to delays and shortages of products such as cars, smartphones, and computers.

The Evolving Supply Chain Landscape

Supply chains have evolved from linear, siloed structures to complex, interconnected networks that span the globe. While this transformation has ushered in unprecedented opportunities, it has also introduced new challenges. Today’s consumers demand faster deliveries, personalized products, and transparency like never before. Meeting these expectations requires a level of visibility that was previously unimaginable.

MarketsandMarkets™: Supply Chain Management (SCM) Market Size, Share & Industry Analysis – Global Forecast to 2027 states that supply chain management market size was worth $28.9 Billion in 2022, and poised to generate revenue of around $45.2 Billion approximately, by the end of 2027, presenting a CAGR of 9.4% from 2022 to 2027.

The key factors driving the growth are market demand for greater transparency, and visibility of supply chain processes. In addition, advancement in the field of technology, integration of AI/ML in SCM systems, presents a lucrative option for SCM vendors and products.

Handpicked Content

Case Study: Realtime Business Visibility & Scalability through Cloud Migration

A Fortune 500 hospitality leader achieved business growth and enhanced customer satisfaction by migrating to the cloud for improved scalability and real-time insights.

Do we truly understand the nuances of supply chain visibility?

At its core, supply chain visibility is about gaining real-time insights into every stage of the supply chain. It involves tracking the movement of raw materials, components, and finished products from suppliers to manufacturers, distribution centers, retailers, and finally, to the end consumer. This visibility extends beyond physical goods and includes data related to inventory levels, order status, and even environmental conditions during transportation.

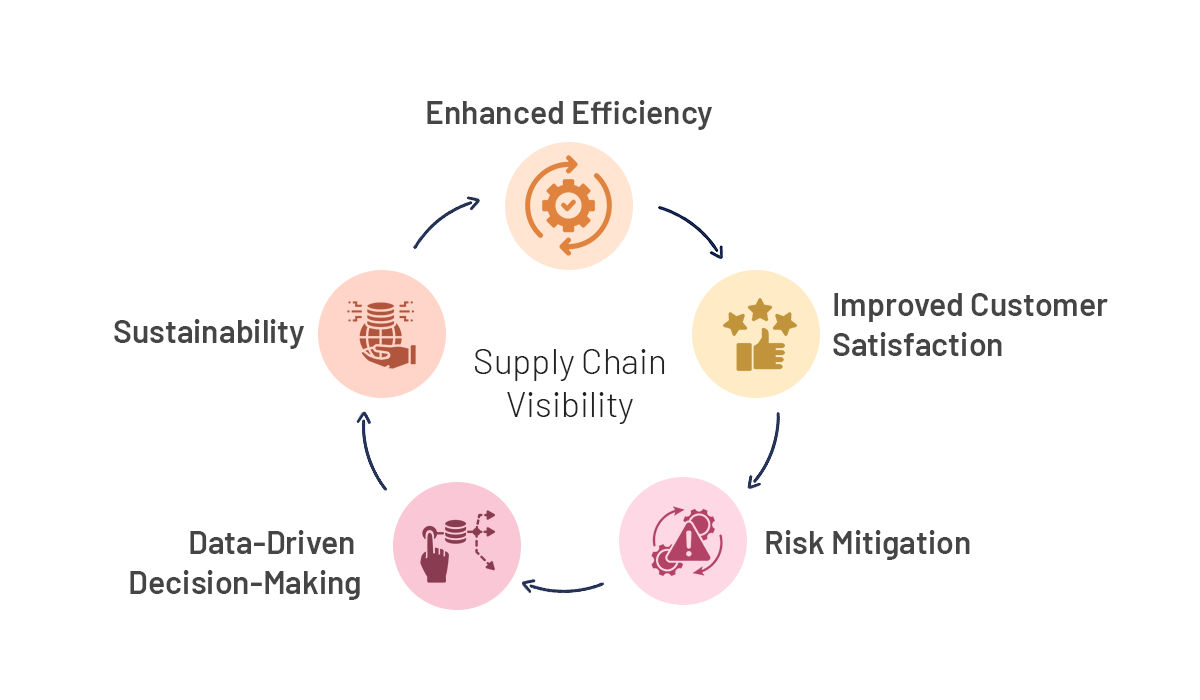

The Benefits of Supply Chain Visibility

1. Enhanced Efficiency: Visibility enables organizations to identify bottlenecks, reduce lead times, and optimize inventory levels. This leads to more efficient operations and cost savings.

2. Improved Customer Satisfaction: Real-time tracking and accurate delivery estimates enhance customer experiences. Satisfied customers are more likely to become repeat buyers and brand advocates.

3. Risk Mitigation: Supply chain disruptions can have catastrophic consequences. Visibility allows companies to identify potential risks early, such as supplier issues, weather-related delays, or geopolitical unrest, and take proactive measures to mitigate them.

4. Data-Driven Decision-Making: Access to a wealth of data empowers organizations to make informed decisions. Analytics tools can uncover trends, identify opportunities for improvement, and predict future demand more accurately.

5. Sustainability: Supply chain visibility also plays a crucial role in sustainability efforts. By monitoring carbon emissions, waste generation, and ethical sourcing, companies can reduce their environmental footprint and meet growing consumer demands for responsible practices.

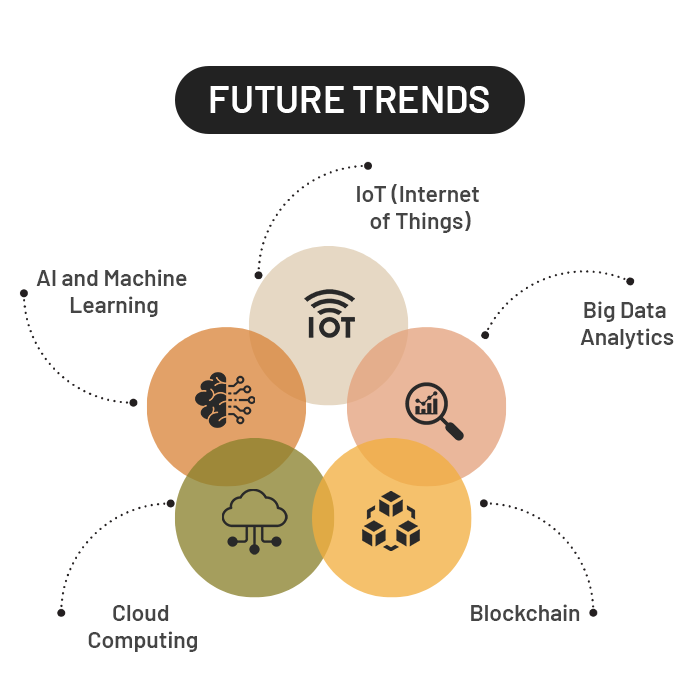

Embracing Opportunities through Tech Visibility

1. IoT (Internet of Things): Sensors and devices embedded in products and containers provide real-time data on location, temperature, humidity, and more.

2. Big Data Analytics: Advanced analytics tools process vast amounts of data, turning it into actionable insights and predictions.

3. Blockchain: Distributed ledger technology enhances transparency and trust in the supply chain by recording every transaction and movement.

4. Cloud Computing: Cloud-based platforms enable real-time collaboration and data sharing among supply chain partners.

5. AI and Machine Learning: These technologies can analyze historical data to identify patterns and make accurate forecasts, improving demand planning and inventory management.

How do big players like Amazon get it right?

The answer is simple, they use a variety of supply chain visibility tools to optimize its delivery routes and ensure that its customers receive their orders on time. For example, Amazon uses real-time GPS data to track the location of its delivery vehicles and make adjustments to routes as needed. Amazon also uses historical data to predict traffic patterns and weather conditions, which helps it to plan the most efficient routes possible.

Handpicked Content

Case Study: Optimizing Shipping Logistics with Accurate Demand Prediction

Learn how a global shipping giant used advanced data analytics to vastly improve demand prediction, revolutionizing their logistics operations in the post-pandemic era.

Pioneering an Era of Transparency in Supply Chain Proficiency

In a scenario where supply chains are the lifeblood of businesses, visibility has become the key to unlocking unprecedented growth and resilience. It’s a beacon that guides organizations through the complexities of global trade and consumer demands. By embracing supply chain visibility, companies can illuminate the path to success, drive efficiency, enhance customer satisfaction, and ultimately, thrive in the ever-evolving business landscape.

Companies should carefully consider their specific needs when choosing supply chain visibility solutions. However, there is no one-size-fits-all solution, and the best approach will vary depending on the size and complexity of the supply chain, as well as the company’s budget and resources.

Unlock real-time insights with our supply chain visibility solutions to improve efficiency and customer satisfaction.